Fastening technology experts

Monday morning, the day starts with a call from a customer. “During the installation of a critical bolt in a braking system, we see it is about to break. At the moment, high-speed trains run with these bolts in the same braking system. Those brakes could fail at any moment. This is an extreme emergency!”

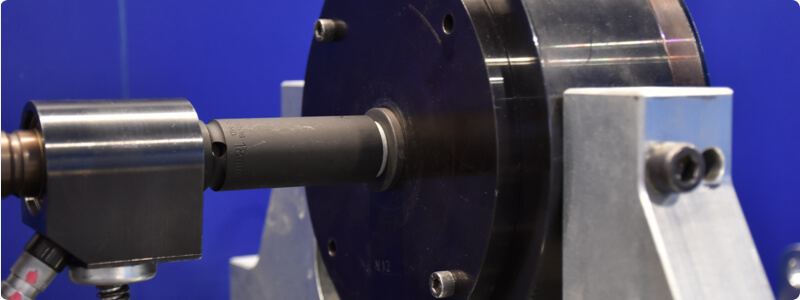

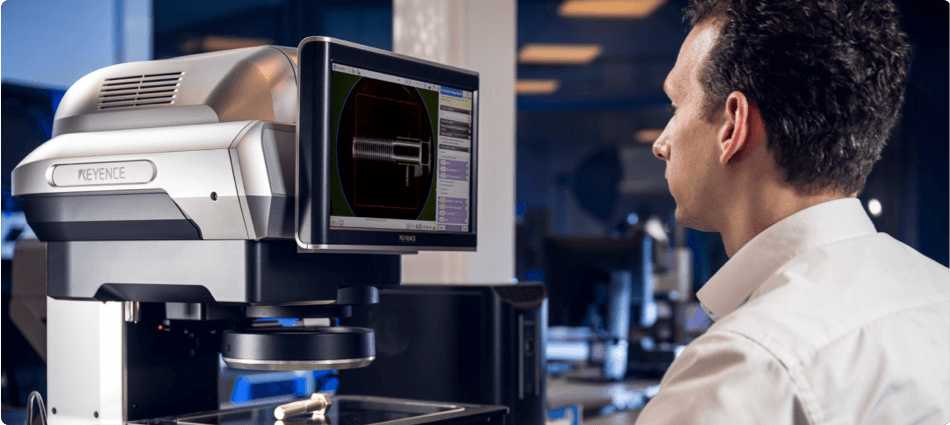

The technical experts of the Quality & Engineering department at Fabory react immediately. Assessed for their mechanical properties in the customer's presence on the same day. Done in Fabory’s accredited laboratory. Examined are the tensile strength, the core hardness and decarburisation. All three are in order according to the requirements of ISO 898-1.