Quality products deserve quality connections

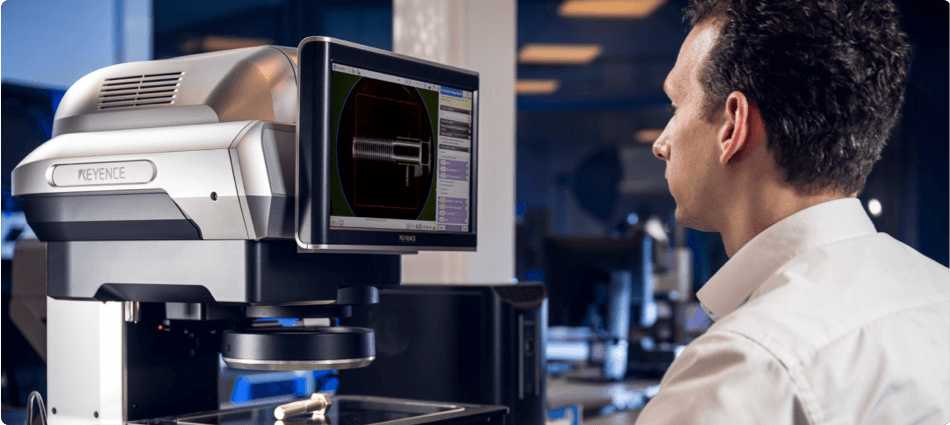

When a customer does not know the answer to a question about a fastening solution, the experts in the Quality & Engineering department come to the rescue. They provide the answers to questions about the complex world of fasteners and connections offering a service that customers can rely on. Failing connections lead to failed applications. Improving a connection leads to better constructions and less aftercare. Quality products deserve quality connections.

A small selection of the questions that customers ask us:

"How long does a surface covering last in a specific application and which material type is most suitable?"

"What preload force can I expect with a tightening torque?"

"How do I prevent a threaded connection from loosening?"

"How much clamping force can a connection exert with an 8.8 bolt?"

"Some 8.8 bolts are broken: can I just replace them with stronger 10.9 bolts?"

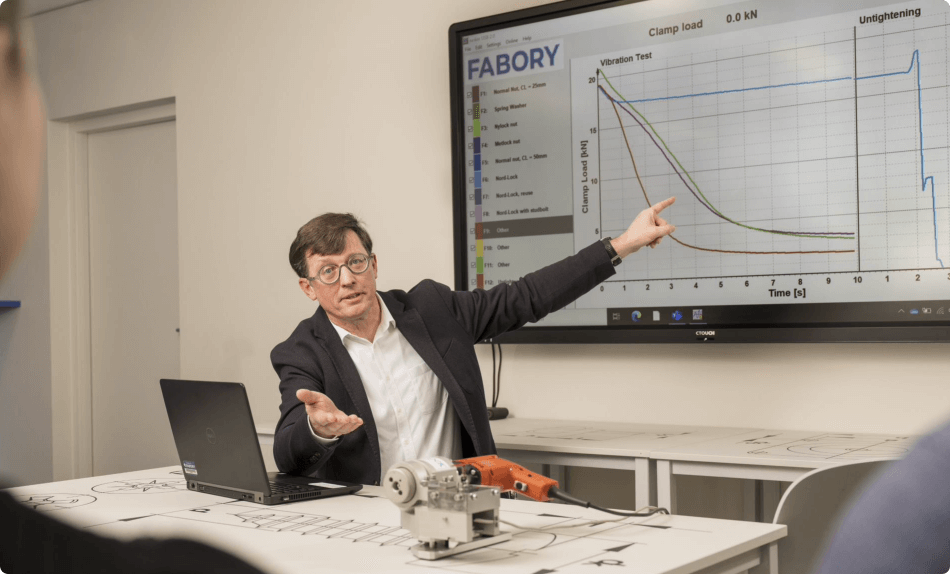

We also capture customer questions in our training offer. With the training offer of the Quality & Engineering department, your knowledge of fastening solutions is kept up to date. A training can be purely theoretical or practical, classroom or online. We tailor the content to your knowledge level and needs.