"In assembling our agricultural machinery, we rely on Fabory Logic"

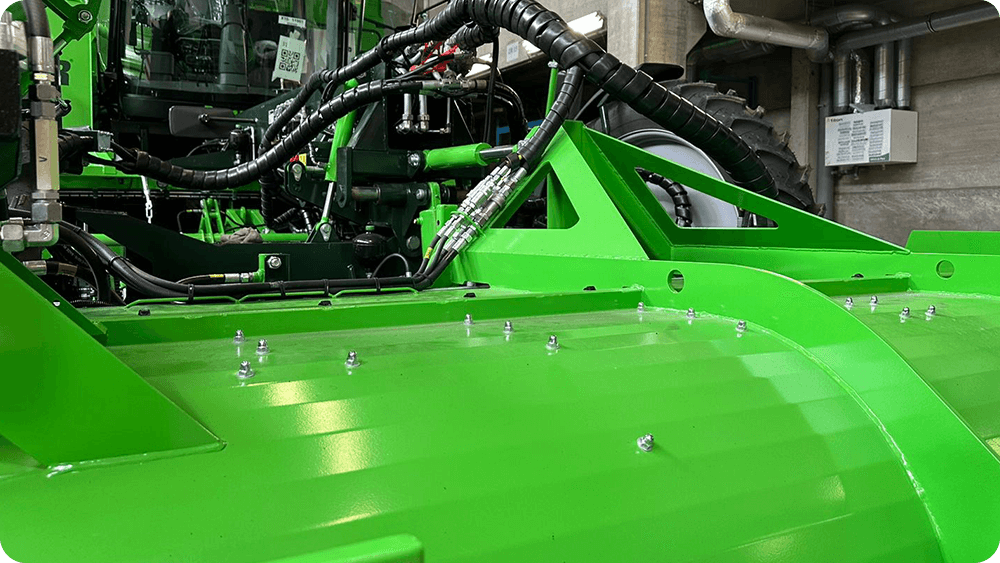

AVR from Roeselare purchases a staggering 99.5 per cent of all bolts, nuts, and couplings used in agricultural machinery from Fabory. By the end of the year, the company produces about 1,000 agrarian machines. During this production, the employees rely on Fabory Logic: with optimal inventory management, employees have access to precisely the right amount of fasteners at all times.

All parts of the machines are custom-made and assembled on the line. During their weekly visit, the merchandiser scans and refills the empty bin on his next visit.

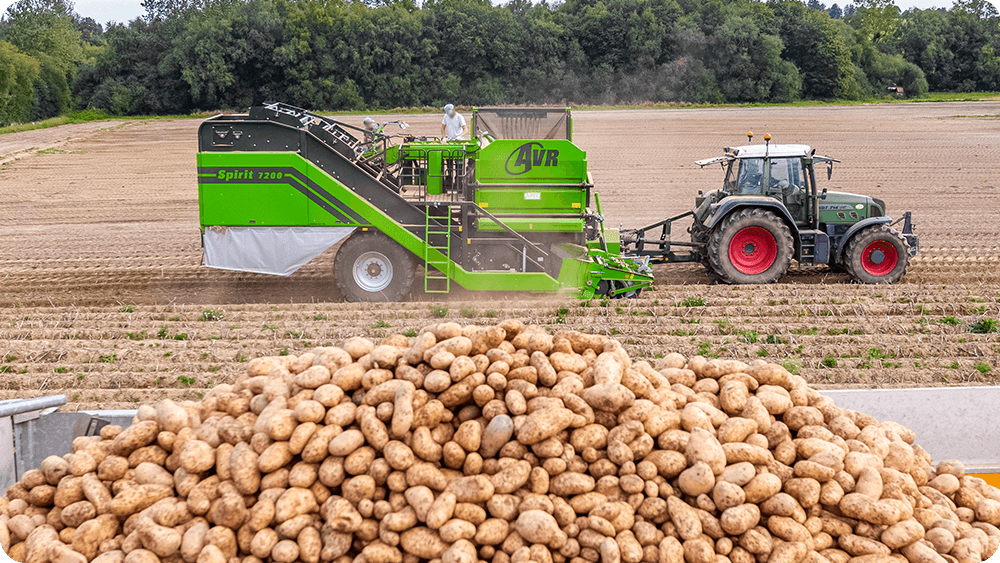

Seasonal production

"Ivan Lippens, an operator at AVR, says: "Should a production stop threaten, I will immediately get in touch with my contact at Fabory." Sometimes, you just need a lot of the same bolts at once, especially with seasonal production." Filip Boone, the tactical buyer, says, "In the past, during busy periods, staff had to open pallets themselves to search for materials. That's a thing of the past with Fabory Logic."

1,000 different materials

There's a high demand for durable machines that offer economic viability. AVR sees a shift towards more precision agriculture. Filip says, "Scale expansion and climate extremes in agriculture/potato cultivation demand better performing and more reliable machines. "The machine must operate within a short time frame and almost no longer tolerates downtime. Staff shortages and qualifications also present a challenge." Machines have to do more under more extreme conditions. Due to less qualified staff, the operation must also be intuitive and simple, which often conflicts with technological progress."

Therefore, AVR pays extra attention in the production process to:

- Reliability and availability of components

- More performant machines: achieving more in the available time

- Remember the text: "Let's add automatic functions to machines that people only use a few weeks a year."

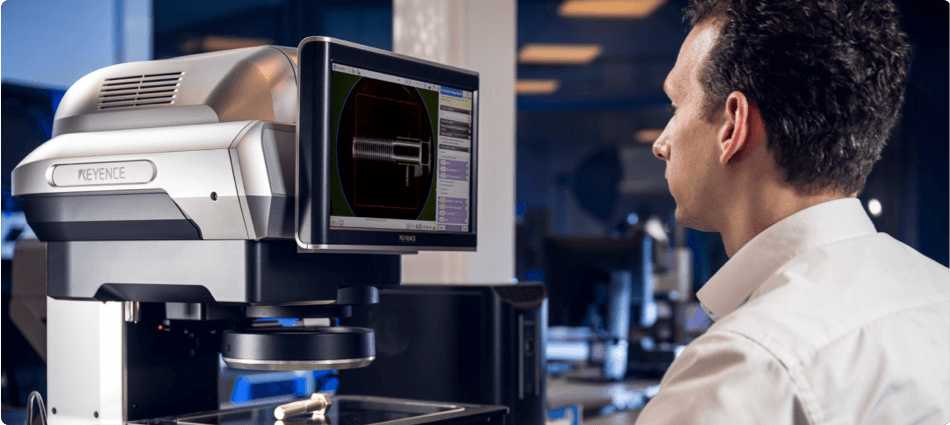

Nowadays, planting machines can place devices that automatically dose fertilisers or pesticides while keeping the environmental impact low. Filip and Ivan's Research & Development department colleagues are searching for new fasteners needed for this addition. They are continuously working on optimising the machines, and we have ordered 1,000 different materials from Fabory.