Laboratory Objectivity

Fortunately for our customers, a scenario like the one in Stuttgart does not happen every week. As soon as the customer's situation calls for it, our Quality & Engineering department switches, and we investigate what could be wrong. We are supported in this research by our laboratory. Fabory's laboratory offers clear added value for customers, and this distinguishes us from other technical wholesalers. Such a private laboratory, is it objective and independent? That's it luckily. In the context of our ISO/IEC 17025 accreditation, an external audit in the laboratory takes place every year. Among other things, this examines the objectivity and neutrality of the laboratory and its employees.

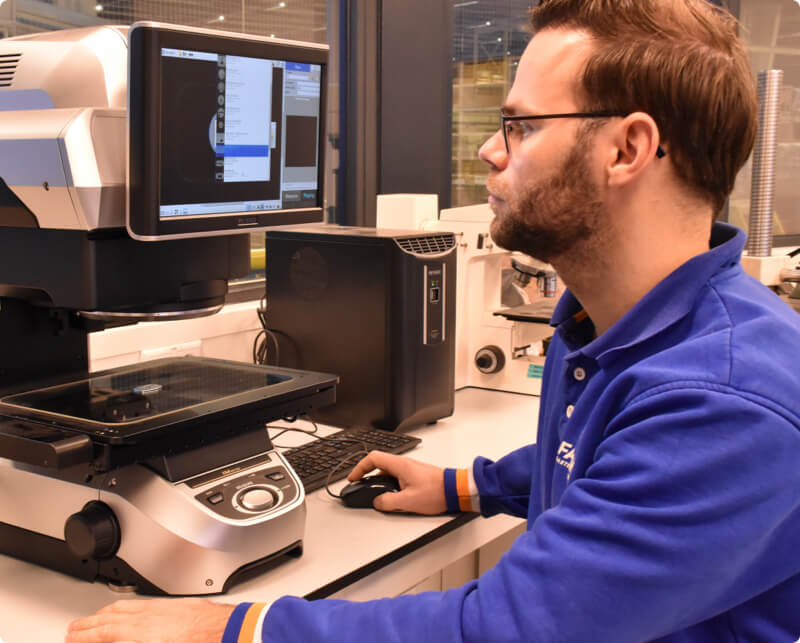

Correct and reliable measurements

Every quarter we receive test samples from a certified organization for which, for example, the chemical analysis or the tensile strength must be determined and reported. These measurement results compared with those of approximately 200 accredited laboratories from around the world, and the results sent to the accreditation board. Every laboratory employee assessed every quarter on the results he achieves in this research. This way of working ensures that Fabory not only performs correct and reliable measurements, but also that the employees carry out the measurements correctly and neutrally.

Customer-specific reports and certificates

A major advantage of having our laboratory is the independence from the supplier when assessing a complaint. If a bolt meets the requirements and a problem nevertheless arises, the Quality & Engineering department can search with the customer for the cause of the problem: this can be in the design, assembly, or application. Then we will come up with a solution. In the accredited laboratory, customer-specific reports and certificates are also drawn up on the basis of measurement results, for example according to EN ISO 16228 F3.1. These certificates are recognised, for example, in the steel construction standard EN 1090-2.