From Your Specifications to Product Drawings and Quality Documents

As a manufacturer in the wind industry, you will have a dedicated point of contact at Fabory, providing a sense of familiarity. We collaborate exclusively with manufacturers who strive for high-quality standards. We source the right supplies according to customer requirements and verify these sources. This ensures full alignment with APQP4Wind certified supply chain practices, mitigating risks in critical wind applications. They are experienced in tracking every detail from the initial specifications to the final product delivery. APQP4Wind is a quality assurance method designed for the wind industry, focused on mitigating risks when introducing new critical items.

Specifications and Standards

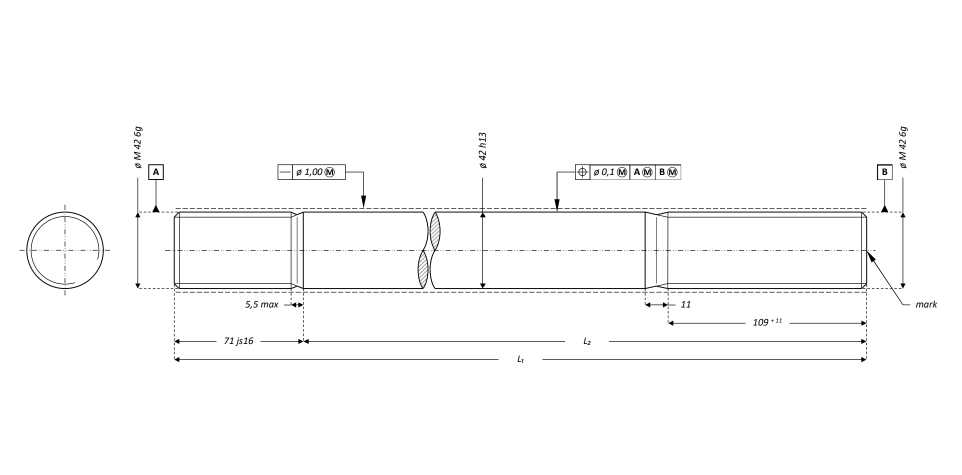

You inform us of your needed items, and we assess our stock availability. In most cases, we create custom items. Based on your specifications, we draft product drawings that guide the procurement process, allowing us to identify suitable manufacturers. We consider mechanical properties, dimensions, and specifications, such as corrosion protection. When establishing specifications, we align with international standards, including those still under development. This allows you to future-proof your supply chain for fasteners in wind energy systems, regardless of changing specifications.

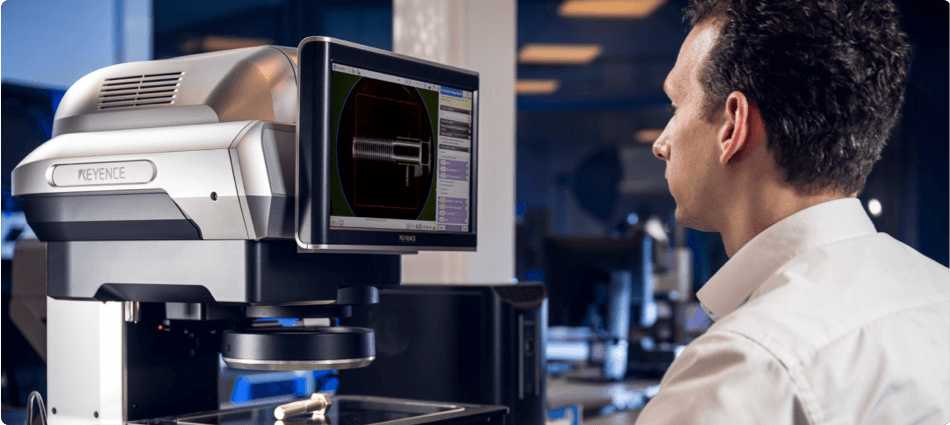

Additionally, our PPAP (Production Parts Approval Process) documents and quality records are carefully checked to ensure they meet the necessary criteria. Every customised item undergoes examination in our laboratory. Only after an item is scrutinised is the supplied batch released for logistics.

Companies in the wind industry appreciate our efficient and seamless collaboration approach. At Fabory, we operate with dedicated teams for each client. Our quality team, specialising in fasteners for wind turbines, is well-acquainted with the specific needs of customers in this sector. We utilise batch management in our ERP system throughout the entire internal logistics process—from receiving goods at Fabory to delivering them to the client. This means every production batch is kept distinct from others and can be traced back to the manufacturer and the client.