The application as a starting point

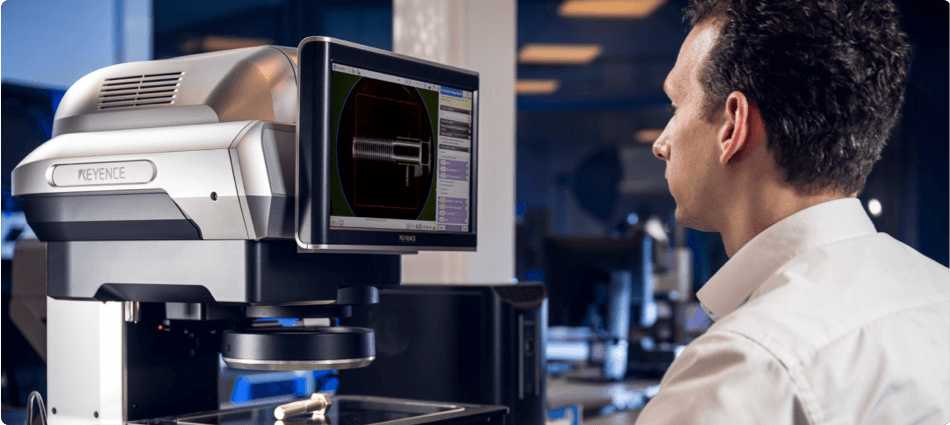

Fabory's Quality & Engineering department experts provide comprehensive advice to customers. One piece of advice is to consider the application of a product first: what should a new solution be capable of? It's essential to ensure that a connection is safe and efficient to mount. Therefore, during the design phase, it's crucial to consider not only the design of the end product but also how to assemble the connection. Fabory's Quality & Engineering department's 3D portal is a valuable resource. The department advises on potential improvements and cost savings even after product use.